WHY Demand Forecasting Is So Important to Supply Chain Professionals and Managers

When I was developing Forecast Decision Support Solutions for corporate clients, I learned the importance of what poor forecasts meant to downstream users in the Supply Chain: Executive managers, logistics managers, financial managers, sales and marketing managers, planners of competitive strategies, production and inventory managers, and others.

That experience is now captured and illustrated in my new book on demand forecasting principles and best practices, available in paperback and Kindle e-book on Amazon. Here are the basic questions to ask when creating a business forecasting process for supply chain organizations:

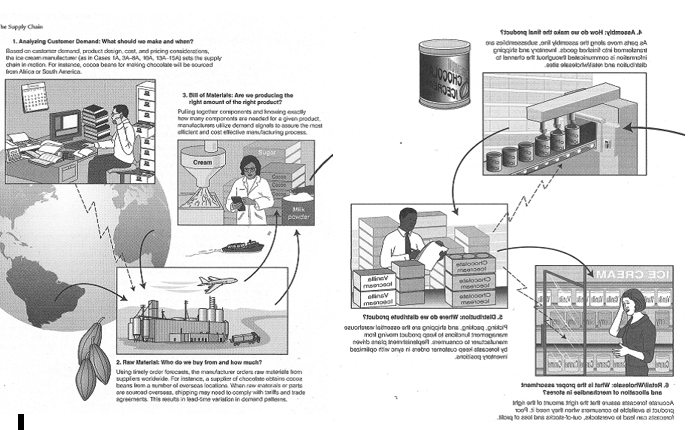

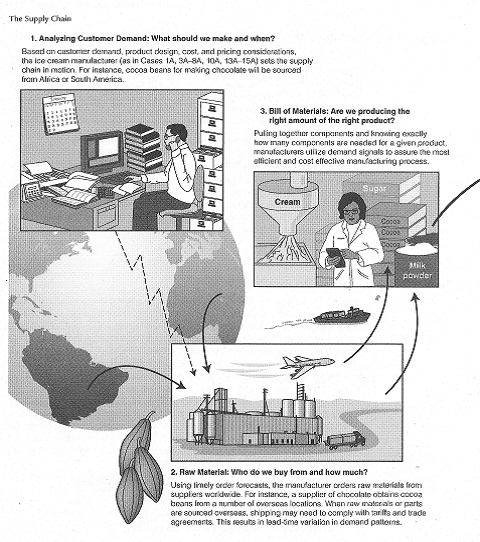

- Analyzing Customer Demand: What should we make and when?

Based on customer demand, product design, cost, and pricing considerations, the manufacturer sets the supply chain in motion. For instance, cocoa beans for making chocolate ice cream will be sourced from Africa or South America.

- Raw Material: Who do we buy from and how much?

Using timely order forecasts, the manufacturer orders raw materials from suppliers worldwide. For instance, a supplier of chocolate obtains cocoa beans from a number of overseas locations. When raw materials or parts are sourced overseas, shipping many need to comply with tariffs and trade agreements. This results in lead-time variation in demand patterns.

- Bill of Materials: Are we producing the right amount of the right product in the right place and the right time?

Pulling together components and knowing exactly how many components are needed for a given product, manufacturers utilize demand forecasts to ensure the most efficient and cost effective manufacturing process.

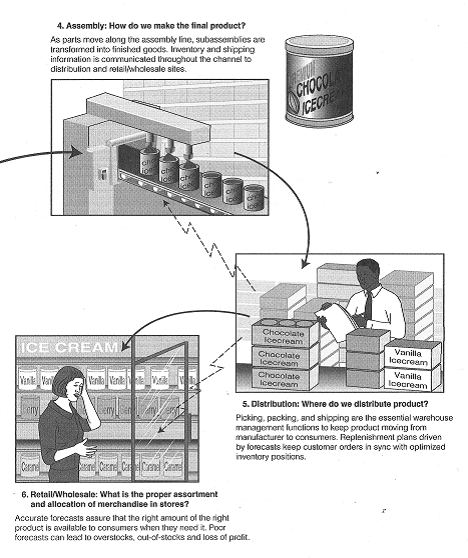

- Assembly: How do we make the final product?

As parts move along the assembly line, subassemblies are transformed into finished goods. Inventory and shipping information is communicated throughout the channel to distribution and retail/wholesale sites.

- Distribution: Where do we distribute product?

Picking, packing, and shipping are the essential warehouse management functions to keep product moving from manufacturer to consumers. Replenishment plans driven by forecasts keep customer orders in sync with optimized inventory positions.

- Retail/Wholesale: What is the proper assortment and allocation of merchandise in stores?

Accurate, reliable forecasts assure that the right amount of the right product is available to consumers when they need it. Poor forecasts can lead to overstocks, out-of-stocks and loss of profit.

If you have a forecasting process visualization of a business or company that you can share with fellow forecast decision makers, please post on my LinkedIn group Demand Forecaster Training and Certification| Blended Learning | Predictive Visualization.

“When I was involved with forecasting several years ago we did not have the ability to incorporate the many methods and computer models that are presented so thoroughly in Dr. Levenbach’s book “Change and Chance Embraced“. In this book the author describes many unique methods and models that can be used in the business environment to provide a more accurate demand forecast. Each chapter has a final section called “Takeaways” which summarizes the chapter and is a helpful insight to its contents.

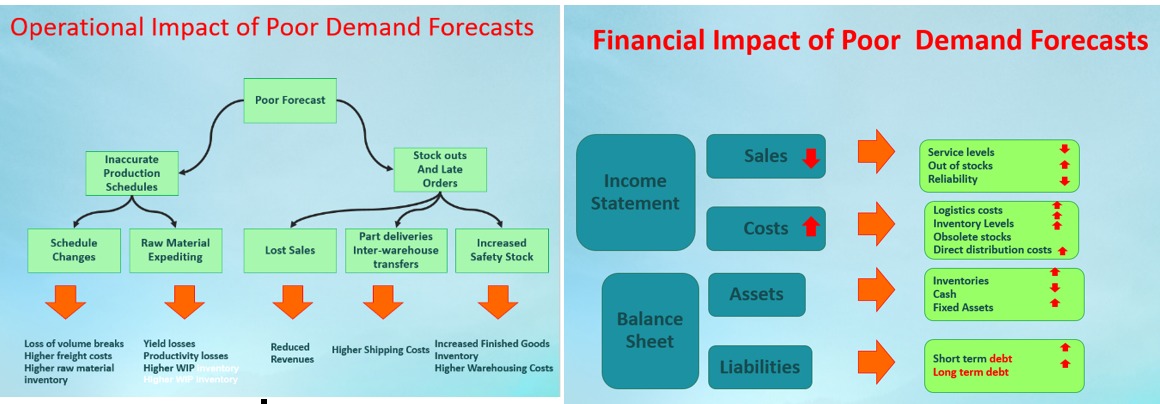

Above and beyond it all we have to realize how important a forecast is to a company. It drives the Balance Sheet, i.e. cash, debt, facilities for manufacturing, etc. It evidently precipitates the Profit and Loss Statement, revenues, gross margin and of course the bottom line income which all of Wall Street will analyze against actual results. This will affect the price of the company’s stock which can help or harm it considerably. In summation, demand forecasting is one of the most important activities a company is involved in and this book with its approaches will definitely improve upon the current forecasts that are currently used.

I highly recommend reading this book too see what it can provide for the improvement of your company’s bottom line.”

Bob T